Is there a difference between OE and aftermarket brake pads?

For most brake pad manufacturers, the short answer is yes. Most friction product producers don’t have OE production knowledge and focus exclusively on aftermarket specifications. Ferodo however, is one of the exceptions, having a strong OE pedigree. This also means top tier friction characteristics like excellent stopping power, longer pad life and noise and dust reduction cannot always be guaranteed when opting for aftermarket braking parts. Simply because they are not made according to the same premium quality engineering standards.

Now how does a car manufacturer pick its preferred type of stock pads? To really secure a high-performing end-product with powerful stopping ability, minimal wear and a performance potential of 50,000 miles of stops, vehicle makers carefully select their components to be designed around their car. Simply because one material can’t cover the full range. This ensures a seamless fit and optimal performance all round. And it’s here braking products boasting real OE quality take the crown. But what if every product coming from a friction manufacturer would sport these same quality requirements?

The Ferodo® approach:

2 markets, 1 standard

Brake pads are at the very core of a balanced braking system. And that’s exactly why from stock pad to aftermarket launch, all friction fundamentals should be honoured. Whether certified Original Equipment or aftermarket brake pad, every Ferodo® friction product passes the same high-end production lines and is manufactured according to the same rigorous engineering standards: a quality guarantee for any distributor, installer and driver.

Let’s dive a little deeper. Every brake pad is designed based on insights from our state-of-the-art R&D centre in Bad Camberg, Germany. Here, scientists and engineers bundle their expertise to test and upgrade every product down to the smallest detail. After extensive trials, both brand-new OE and aftermarket product launches will be developed in OE production plants like the ones in Mondovi, Chapel-en-le-Frith or Kostelec.

In these facilities, top of the line machinery and dedicated workforces design premium friction products that bear the Ferodo® OE Original Quality seal: your label for powerful stopping ability, minimal wear and a long lifespan. When choosing brake pads or other braking products, finding the right fit comes down the vehicle type. All you need to do is make a list of brake pad must-haves, and get started! We’ve summed up our essentials here.

OE original quality: your premium guarantee

Pro tip: when buying friction products for a specific vehicle, be sure to choose OE quality parts. OE quality friction products achieve optimal friction due to the OE specifications they are designed to meet. Stringent metallurgical tests assure they perform optimally, even in the most extreme situations. This also means OE quality aftermarket parts can measure themselves against any other Original Equipment products on the market. OE is a long-standing label for top tier parts: it’s a real benchmark for many of the world's manufacturers of cars, vans, trucks, trailers and buses. In Ferodo®’s case, both OE and aftermarket braking products boast the OE Original Quality label for optimal performance.

Ferodo® as the automotive benchmark

Because Ferodo® parts are either Original Equipment or OE quality compliant, they bring added safety, reliability and quality features with them. This also means Ferodo® treats OE and aftermarket products as equally important for distributors, installers and drivers. As the official OE partner of most major car manufacturers, servicing 100 top-selling cars on the automotive market, many of our braking products are specifically developed and selected for the vehicle manufacturers themselves.

And with 14 production facilities worldwide producing over 40 million brake pad pieces globally each year, it's safe to say we've got you covered with top of the line building blocks for all automotive needs, well-trusted around the globe.

Your Ferodo®

OE Quality Benefits

General qualities

- In-house R&D for premium quality standards

- OE & aftermarket on same production line

- Top performance in stopping power

- Consistent pedal feel and response

Easy part fitment

- Leading range and optimal car parc coverage

- Mounting accessories in the box to match OES specification

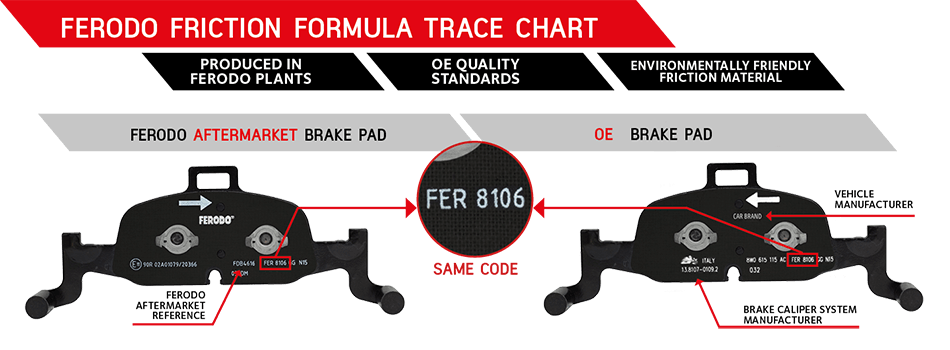

- Consistent engraving for total traceability

Longer pad & disc life

- Prolonged lifetime & improved performance with outstanding heat dissipation

- Enhanced durability thanks to excellent metallurgy and design

Improved driver safety

- Non-directional finish with better brake pad/disc matching

- Shorter stopping distances & improved brake performance during bedding-in

- Top-quality casting process drastically reduces risk of brake failure & accidents

Enhanced driver comfort

- Higher vibration damping keeps judder & noise to a minimum

How to spot genuine Ferodo® parts?

INSIDE THE BOX

To be sure you're holding an official Ferodo® brake pad in your hands, read the unique Ferodo® formula on any aftermarket or OEM brake pad to check its validity. Use the official Ferodo® Friction Formula Trace Chart below to get informed on how to check your own Ferodo® products instantly.