Pioneering Technology

FUSE+ TECHNOLOGY

PERFORMANCE MEETS COMFORT

Fuse+ Technology Brake Pads is a story about joining forces, combining expertise.

From R&D to instalment, trusted power to high-end comfort: this all-new tech innovation builds bridges.

PIONEERING INNOVATION

PIONEERING INNOVATION

Backed by 3 years of dedicated engineering and 75 materials tested. The FUSE+ Technology.

Brake Pad is a unique combo of 20 components and takes brake pads to the next level.

TECH FEATURES

TECH FEATURES

The FUSE+ Technology Brake Pad has the same zero-copper Eco Friction® tech, emits less wheel dust, and even less noise and cuts emissions. All with enhanced pad and disc durability for an extended lifespan.

OE MATCHING QUALITY

OE MATCHING QUALITY

Expect world-leading product characteristics with each stop. Every FUSE+ Tecnology Brake Pad is meticulously engineered in R&D centres like our Chapel-en-le-Frith Tech center in the UK. After development, it’s produced to OE standards in our class-leading sites in Europe. To meet the high OE requirements. No matter the situation.

REVOLUTIONARY BRAKE PAD

REVOLUTIONARY BRAKE PAD

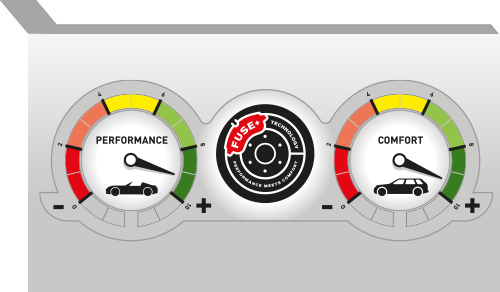

- OFFERING BEST OF BOTH WORLDS

Fuse+ Technology has been engineered to bridge the gap between performance materials, and comfort-oriented materials. This philosophy has resulted in a revolutionary brake pad formulation, offering best of both worlds.

ultimate comfort

ultimate comfort

These pads bridge the gap between performance and todays environmental needs, whilst also creating quieter longer lasting brakes. They're just great on wear, noise, dust and feel extremely good.

ECO-FRICTION®

THE ECOLOGICAL OE TECHNOLOGY

Green, safe and with outstanding stopping performance. Eco-friction® technology allows for low to zero copper brake pad formulations reducing heavy metals and emissions. This on-trend innovation meets the needs of the latest eco-friendly platforms.

- 5 years of dedicated engineering centers

- 1,500 materials tested for a five-star formulation sustaining the same binding effect as copper

- Combo of up to 25 different components: metal sulphides, minerals, abrasives, fibres, ceramic particles and types of graphite

- Fit for all types of vehicles, including hybrids & electrical cars also, highly efficient for electric parking brakes

GREENER, SAFER AND LIGHTER

GREENER, SAFER AND LIGHTER

<0,5% of heavy metals concentration

Particles of copper, zinc or antimony

-60% of emissions through weight loss (pad/disc)

as of distance of 7,000 km

MAKE YOUR GREEN CAR ECO-FRIENDLIER

MAKE YOUR GREEN CAR ECO-FRIENDLIER

Electrical and hybrid vehicles have higher brake pad requirements due to no engine-generated noise, regenerative braking, gross vehicle weight and acceleration power. Eco-friction® meets these needs.

- Overall higher stopping performance

- More stable friction level in different conditions

- Higher requirements for noise vibration harshness (NVH)

THE WORLD'S FIRST DEDICATED BRAKE FLUID FOR ELECTRIC & HYBRID CARS

THE WORLD’S FIRST DEDICATED BRAKE FLUID FOR ELECTRIC & HYBRID CARS

THE WORLD’S FIRST DEDICATED BRAKE FLUID FOR ELECTRIC & HYBRID CARS

The global market for electric and hybrid vehicles is expanding rapidly. But these new cars have new needs. To achieve a safe and smooth stopping performance, an enhanced fluid was needed. A fluid optimised for EHV models.

LOWER CONDUCTIVITY

LOWER CONDUCTIVITY

Due to potential electrical currents in the vicinity of the brake system, Ferodo designed a new type of fluid with a lower conductivity.

HIGHER DRY AND WET POINTS

HIGHER DRY AND WET POINTS

EHV models won’t be able to take advantage of regenerative braking when the battery is full. The traditional brakes will have to do all the work. A dedicated brake fluid is recommended then to address the perpetual braking needs. Ferodo engineered a fluid with a high dry and wet boiling point to ensure maximum safety, comfort, and durability for EHVs.

BETTER CORROSION RESISTANCE

BETTER CORROSION RESISTANCE

Under normal circumstances, the brakes of EHV models are used less. But they still have to work perfectly when needed. That drove Ferodo to develop a fluid with enhanced corrosion protection.

The EHV brake fluid exceeds almost any spec including DOT 3, DOT 4, DOT 5.1, and DOT 4LV.

WHY DO ELECTRIC & HYBRID VEHICLES NEED A DIFFERENT BRAKE FLUID?

WHY DO ELECTRIC & HYBRID VEHICLES NEED A DIFFERENT BRAKE FLUID?

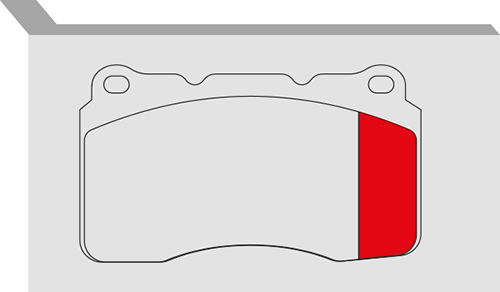

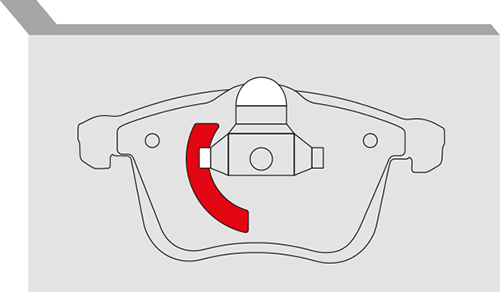

DIRECTIONAL BRAKE PADS

For a quieter braking system that performs at the same high standards as standard brake pads. Because directional brake pads touch their brake discs at an angle, brake noise, vibrations and harshness (NVH) are reduced to a minimum.

CREATED WITH A CHAMFER

CREATED WITH A CHAMFER

OR CUT-OUT

Chamfer directional brake pads use a transitional surface between two sharp edges on the friction surface. This prevents the leading edge of the brake pad from lifting the brake disc, induces even pad wear and reduces noise.

Crescent cut-out directional brake pads cut a crescent shape from the reduction shim on the backing plate. This reduces vibrations and acts as a thermal barrier for even temperature distribution.

HOW TO INSTALL

HOW TO INSTALL

DIRECTIONAL BRAKES

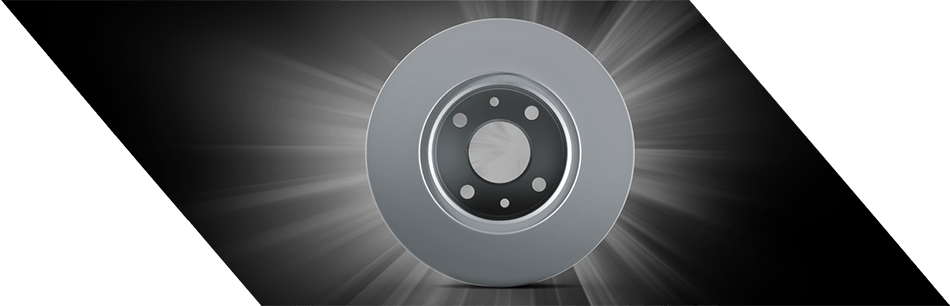

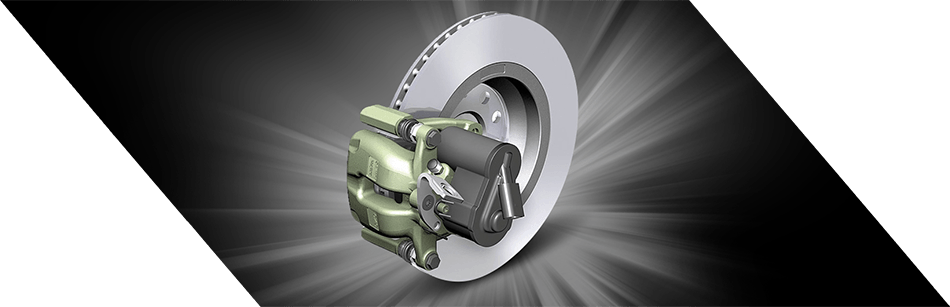

COAT+ TECHNOLOGY

LESS OXIDATION, INSTANT FIT

Best fitted with Ferodo Eco-friction® brake pads, Coat+ Technology eliminates de-greasing prior to installation and provides excellent corrosion protection for selected applications. All without compromising on performance.

- Outstanding coating to avoid disc service oxidation

- Allowing for immediate fitting of the part

- Covering a wide range of vehicles, including modern top-of-the-range vehicles with alloy rims

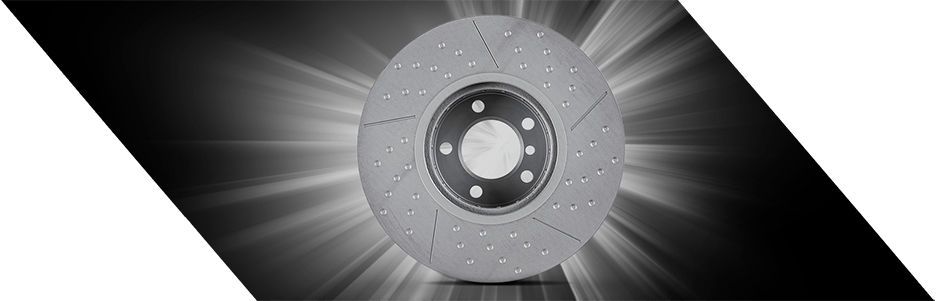

COMPOSITE ROTORS

TECHNOLOGY

STATE-OF-THE ART BUILD QUALITY

- Combining high carbon cast iron braking surface & lightweight aluminium bell

- Connected via a stainless steel pin

MAXIMUM PRECISION & PERFORMANCE

- Enhances braking performance

- Matching in Design & Performance of the latest OE technical innovations

LIGHTWEIGHT CONSTRUCTION

- Up to 30% weight reduction compared to an average brake disc

- Reduced vibrations

- Reduced fuel consumption & emission

THE POWER OF PERFORMANCE

- Result of continuous research & development

- For unmatched driving comfort

- Sporting outstanding durability

ELECTRIC VEHICLES

To meet the EU emission targets set up for the next 5 to 10 years, a more electrified fleet will be necessary. With barriers like affordability, infrastructure and lack of investment slowly dissapearing, the road to pure electric is opening.

GLOBAL ELECTRIC CAR SALES SOAR

2019 sparked a boom in the worldwide sales for pure eletrical vehicles. With an increase of 92% to 765,000 units sold in 41 different markets in the first half of this year, the electric craze is expected to accelerate further in the upcoming months*. It is an electric revolution that calls for a technical one.

DIFFERENT TECHNOLOGY, NEW NEEDS

From reducing the weight of the actuators to lowering brake squeal and mechanical creep behaviour, Ferodo® has already answered this automotive evolution to provide safe braking in all situations, even with a regenerative braking system acting as a generator to turn the car's momentum into electricity. Count on optimal effciency, comfort and performance with every drive.

*JATO Automotive Market Research 2019

ELECTRONIC HAND BRAKE

Increased accuracy, greater efficiency, better emergency control... these are just a few benefits electric hand brakes provide over the traditional system. It shouldn't surprise anyone that the mechanical hand brake is slowly being replaced by today's car manufacturers. What does this greater ease of use, reliability and better functionality mean for your brake pads?

GREATER BRAKE PAD REQUIREMENTS

- High & stable static friction to park vehicle on slopes

- No brake squeal

- No creep groan