Rear brakes

BRAKE PADS

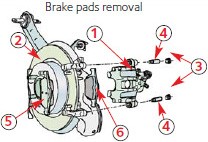

brake pads: REMOVAL

- Position vehicle onto lift.

- Switch the vehicle off and remove the key from the ignition.

- Remove rear wheels.

- Release park brake.

- Remove park brake cable (1) and caliper retainer (2).

- Using the correct size spanner remove the caliper mounting bolts (4), and free the caliper from the hub section .

- Remove outer (5) and inner (6) brake pads.

brake pads: REPLACEMENT

- Retract the piston back into the caliper housing using the brake piston retraction tool.

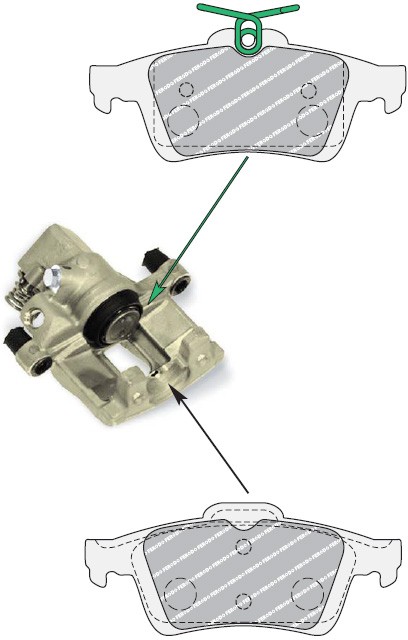

- Fit outer brake pad on wheel side (without retaining clip).

- Fit inner brake pad on piston side (with retaining clip).

- Tighten brake caliper to mount retaining screws to a torque of 35 Nm.

- Adjust parking brake travel.

- Bleed hydraulic system (as indicated in the "Hydraulic Circuit" section).

BRAKE DISCs

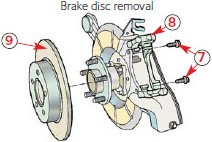

brake discs: REMOVAL

- Position vehicle onto lift.

- Switch the vehicle off and remove the key from the ignition.

- Remove rear wheels.

- Release park brake.

- Remove park brake cable and caliper retainer.

- Using the correct size spanner remove the caliper mounting bolts, and free the caliper from the hub section.

- Remove brake outer and inner pads.

- Remove brake caliper hose coupling.

- Loosen the caliper mounting bolts (7) and remove the caliper mounting bracket (8).

- Remove brake disc (9) from hub.

brake discs: REPLACEMENT

- Ensure the wheel hub is clean and corrosion free and that the disc surface is clean and smooth

- Position brake disc onto hub by sliding it onto stud bolts.

- Using the correct specialist tool, push the caliper piston fully home into the caliper.

- Fit brake caliper mounting.

- Tighten brake caliper mount retaining screws to a torque of 70 Nm.

- Position the caliper in place and refit the Caliper mounting bolts.

- Fit the new outer brake pad on the wheel side of the hub.

- Fit the new inner brake pad on the piston side of the caliper.

- Tighten the brake caliper mounting bolts to a torque of 35 Nm.

- Tighten hose coupling to caliper to a torque of 15 Nm.

- Adjust park brake travel.

- Bleed hydraulic system (as indicated in the "Hydraulic Circuit" section).

WARNING: When retracting the piston back into the caliper housing, brake fluid is pushed into the reservoir. When moving the caliper, ensure the caliper is supported. Make sure that brake pad contact points are clean and free from any contamination.

BRAKE PADS ASSEMBLY PRECAUTIONS

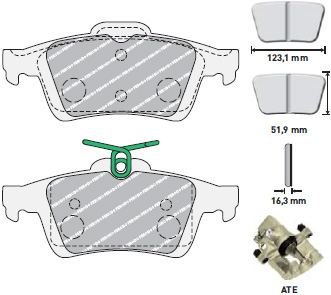

WARNING: To ensure correct rear brake operation, it is critical to fit the brake pads correctly as per the diagram below. The rear pads if fitted wrong will give uneven wear, noise and poor performance. The reason is that the caliper construction does not allow for the anti-rattle spring to fit in the outer edge of the caliper bridge and as such does not allow the pad to sit flat to the disc. The inner pad will rattle when the brake is not being applied.

OPERATIONAL PRECAUTIONS

Brake fluid is hygroscopic, and it should be changed at regular intervals. Do not use fluid which does not comply with the specifications indicated in the table. Take care not to let fluid accidentally drop onto painted, rubber, plastic and mechanical parts. Do not use brake fluid from a container that has been open for an extended period of time.

PARKING BRAKE

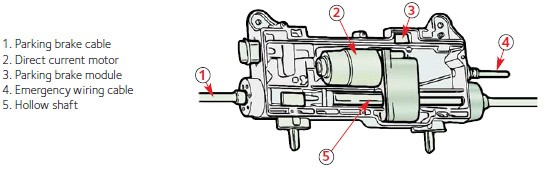

ELECTRONIC PARK BRAKE OPERATION

Certain models may have been fitted with the optional Electronic Park Brake system. This system includes a special key, a clutch pedal switch, a brake pedal switch, an emergency brake release mechanism and an actuator positioned under the spare wheel compartment. The only user interface is the Electronic Park Brake Switch or toggle which actuate the Park Brake.

The electronic park brake lock can be one of two types, namelystatic braking or dynamic braking:

during static braking, at a speed below 4 km/h or with the vehicle stopped, the key is pulled up shortly to lock brake;

during dynamic braking, at speeds above 4 km/h, the key is pulled up to achieve a gradual braking effect.

ADJUSTMENT

WARNING: Procedure applying only to the mechanical parking brake. A diagnosis tool must be used for the Electronic Park Brake.

Note: Before adjusting a new or re-routed cable, make sure that the brake lever is completely released, and allow system settling in the four following steps:

- Step 1: Tighten adjuster nut to a torque of 2 Nm.

- Step 2: Lift parking brake lever by twelve notches.

- Step 3: Release parking brake lever all the way down.

- Step 4: Loosen nut and slacken off until the end of the thread is reached.

- Remove the dust seal cover from the parking brake controllever.

- Disable the parking brake.

- Make sure that parking brake cable is correctly routed.

Note: Do not exceed the recommended torque of 2 Nm. Do not turn the adjuster nut by more than 23 turns. Failure to comply with these recommendations can lead to cable threading damage.

- Make sure that the parking brake lever is fully released, and adjust the brake cable in the four following steps:

- Step 1: Insert a 0.7 feeler gauge between the parking brake lever and the cam assembly pin on both sides.

- Step 2: With the help of another operator, tighten the adjuster nutuntil a movement on one of the parking brake caliper levers can be visible.

- Step 3: Remove feeler gauge.

- Step 4: Spin the rear wheels and check if there is any brake hard point. Should this be the case, loosen the parking brake adjuster nut until threading end, clean the parking brake cables, and repeat the adjustment procedure.

- Fit the parking brake control lever dust seal cover.

HYDRAULIC CIRCUIT

BLEEDING

Warning: During bleeding, always pour new and clean brake fluid inside reservoir

- Connect the bleed pipe to the bleed screw.

- Ensure the other end of the pipe is positioned in a catch reservoir containing a small amount of brake fluid.

- Position bowl bottom at least 300 mm above bleeding screw.

- Loosen bleeding screw by half a turn.

- The best place to start brake bleed is furthest away from master cylinder. A pressure bleeder is recommended.

- Fill reservoir with brake fluid to the Max. mark.

- Continue pressing brake pedal until clean and air-free brake fluid is pumped into the catch reservoir.

- Once the pressure bleeding is complete and the air is out the system, tighten the bleed screw.

- Apply brake pressure using the foot brake and check for leaks.

Warning: Ensure the bleed screw is tightened and the dust cap is replaced to prevent corrosion.

- Repeat the same procedure for the other brake lines.

| BRAKE FLUID | |

| Product | DOT4 |

| Maintenance intervals | Change and bleed every 2 years |

| Level check every 20,000 Km/1 year | |

| Visual check for leaks or rustevery 20,000 Km/1 year | |

| BRAKE FLUID DOT4 | ||

| FBX050 | 500 ml |  |

| FBX100 | 1 lt | |

| FBX500 | 5 lt | |

| FBX2000 | 20 lt | |

| FERODO PART NOS. |

| Brake Pads | FDB1931 |

|

|

| Brake Discs | 15" and 16" rims | 17" rims |

| Series Part No. | DDF1226 | DDF1227 |

| Diameter (mm) | 265.0 | 280.0 |

| Thickness (mm) | 11.0 | 11.0 |

| Min. thickness (mm) | 9.0 | 9.0 |

Note:

Besides on Ford C-Max, this type of ATE caliperis assembled also on some versions of:

- Ford Focus II/Tourneo Connect/Transit Connect

- Mazda 3/5

- Volvo C30/S40/V50