BRAKE NOISE

Brake noise is one of the major reasons for a driver to visit a workshop. It can be a complex issue and is often difficult to solve.

A.WHAT IS BRAKE NOISE?

Brake noise typically originates from vibration on a part within the wheel end section of the vehicle – between the tire and the connection to the chassis. Noise is often blamed on the brake pad itself but can come from any part, from the wheel bearing to the ball joint. Within the brake system, it’s normal to have some vibration, but it is not usually intense enough to be audible.

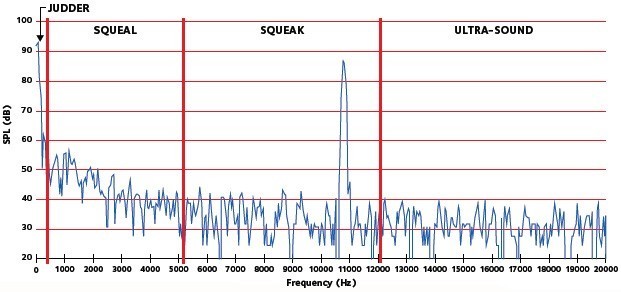

TYPES OF NOISE EXPERIENCED BY DRIVERS CHART

B. Symptoms and Remedies

Tapered Pads

- APPEARANCE: Uneven wear, tapered pads

- CAUSE: Distorted caliper, caliper slides sticking, excessive caliper clearance

- EFFECT: Premature pad wear, uneven braking pressure, noise

- REMEDY: Replace pad set, maintain & service caliper

Uneven Wear

- APPEARANCE: Uneven wear on pad surface

- CAUSE: Irregularly worn brake disc (a wear lip will be visible on the disc)

- EFFECT: Squeal & judder, premature pad wear

- REMEDY: Replace brake discs and pads

Uneven Wear Within Axle

- APPEARANCE: One or more brake pad within the axle set will be excessively worn

- CAUSE: Caliper guide pins or piston sticking

- EFFECT: The vehicle pulls to one side while braking, uneven & rapid pad wear, squeal & judder

- REMEDY: Maintain all caliper slides & pistons, replace pads. Check discs

Damaged Back Plate

- APPEARANCE: Damaged back plate

- CAUSE: Incorrect assembly, excessive force used during fitting

- EFFECT: Braking inefficiency, irregular wear, noise & judder

- REMEDY: Replace full brake pad set

C. Avoiding Noise Problems

The easiest way to avoid problems is to ensure that the brake pads and caliper are correctly assembled.

Tips for correct assembly:

Strip and clean all the caliper slides and pins. Emery paper can only be used on the caliper and pad abutments in the case of heavy rust or pollutants.

Note: if the caliper is not sliding easily, this can result in tapered pads or uneven wear within the axle, which creates squeal and judder.

The pins must have the correct lubrication to ensure free movement so that the pin does not seize into the caliper body. Also, check the condition of the slide pin rubber boots to stop water ingress.

Note: if the pins are not lubricated they may seize, causing wear taper and noise issues.

Check that the brake pads fit freely and easily into the caliper brackets. Clear burrs off the brake pad edges if required.

Note: if the pad is not moving freely inside the brackets, there will be ongoing contact with the discs, causing squealing as well as tapered pads or uneven wear within the axle.

In certain cases (e.g. an old rusted caliper), it is a good idea to lightly lubricate the contact points between the metal back plate and slides with copper grease, according to the vehicle manufacturer’s instructions.

Note: take care that NO grease touches the friction material.

Insert wear indicators, when appropriate, in or on the brake pads.

Screw in the caliper fixing bolts.

Replace the thread-lock bolts with new ones.

Follow the correct tightening torque and sequence recommendations.

With the brake caliper reassembled, pump the brake pedal until the stroke is around one-third of the full stroke potential.

Check that the brake operates correctly, including pad retraction.

Refit road wheel. If there is a free rotation, the vehicle is ready to go back on the road.

Note: do a road test before returning the vehicle to make sure that the brake system is in full working order. When you return the car to the driver, advise them on the correct bedding-in procedure to ensure proper brake efficiency. We have created a handy.

Driver Tips leaflet you can use for this purpose – ask your local representative.

English

English